Multicore Automatic Back-Flushing Filter

Product Description

Multi-core automatic back-flushing filter is used to filter suspended particles in water to meet the cleanliness requirements of working water in various industries. The device consists of housing, filter disc, backwashing swing arm, motor speed reduction mechanism, sewage electric valve, pressure gauge, pressure(differential) sensor, electric control box, etc., which can be used in steel, metallurgy, energy, power, electronics, medicine, food, printing and dyeing, papermarking, coal, municipal engineering and other industries water treatment and filtration systems.

Working Principle

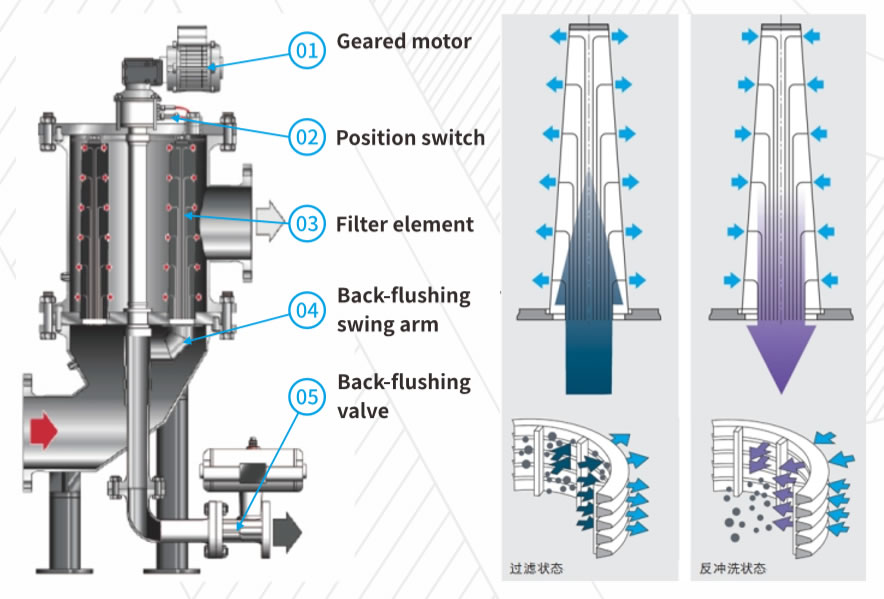

Multi-core automatic back-flushing filter has multiple filter elements installed. When the filter is in filtering state, multiple filter elements work at the same time. When the filter is in reverse flushing state, only one filter element is backflushed. The remaining filter elements work normally, and the back flush water is clean water which comes from other filter elements.

Flow Direction

Unfiltered liquid enters the filtering equipment from the inlet of the lower part of the cylinder, enters the inside of the filter element through the lower fixing plate, and the liquid flows from the inside of the filter element to the outside, and flows out from the outlet of the middle of the cylinder. discharge.

Filtration Process

During the flow of liquid from the inside of the filter element to the outside, solid particles are trapped inside the filter element. As the pollutants increase, the pressure difference between the polluted and clean sides of the filter element gradually increases. The system starts the automatic back-flushing process

Back-flushing Process

The electrically powered gear motor rotates the back- flush arm below the filter element or elements to be cleaned and stops.

The back-flushing valve is opened by a pneumatically operated rotor drive and the filter element or elements are cleaned.

The pressure drop between the filtrate side and back-flush line flushes a small amount of the filtrate back through the contaminated filter elements.

The contaminant particles deposited on the inside of the filter elements are detached and carried away via the back-flush arm into the back-flush line.

After the “back-flush time per filter element” has elapsed, the back-flushing valve is closed. The gear motor now rotates the back-flush arm further to the next filter element(s) to be cleaned.

The back-flushing valve is opened once again and the filter element or elements are back-flushed.

A complete back-flushing cycle is terminated once all filter elements have been cleaned.

Main Performance Parameters

- Filtration accuracy range: 25μm ~ 3000μm can be arbitrarily selected;(Wedge mesh 50μm ~ 3000μm, composite sintered mesh 25μm ~ 100μm)

- Working pressure range: 0.15 ~ 1.6MPa;

- Pressure level: 0.6MPa, 1.0MPa, 1.6MPa (The pressure can be customized);

- Medium temperature: 0 ~ 65 °C;

- Equipment initial pressure drop (clean water): ≤02MPa;(For filtration accuracy ≤550um, the initial pressure drop is increased by about 50%);

- The inlet and outlet are connected by flanges;

- Automatic back-flushing control mode: Differential pressure, Time, Manual control;

- Back-flushing: Adjustable from 0 to 60s.

Special Features

- The filter element is conical type to avoid turbulent and countercurrent flow of the liquid, to ensure maximum filtration efficiency during filtration, and achieve the best flushing effect during back-flushing;

- For the wastewater treatment industry, the filter element can be treated with a special coating to reduce the adhesion of particulate dirt on the surface of the filter element, improve the efficiency of back-flushing, and extend the interval between two back-flushing cycles;

- Optimized liquid flow design, the filter structure is more compact, while achieving higher filtration efficiency and smaller pressure drop;

- Use the pneumatic valve for the back-flushing valve, which can be quickly opened and closed, forming a time pulse at the outlet of the back-flushing filter element, and enhancing the back-flushing effect during the back-flushing process;

- High back-flushing intensity, high b back-flushing effect and short time consumption;

- Low water consumption, back-flushing water consumption: about 1% to 3% of filtered water;

- Suitable for occasions with poor water quality and large amount of treated water,

- Large filtering area, low flow rate, small hydraulic loss and long back-flushing cycle;

- It can achieve continuous online work, and the filter flows continuously during back-flushing, reducing downtime maintenance costs;

- Corrosion-resistant and explosion-proof filter can be provided according to working conditions;

- Simple structure, easy maintenance and wide application range.

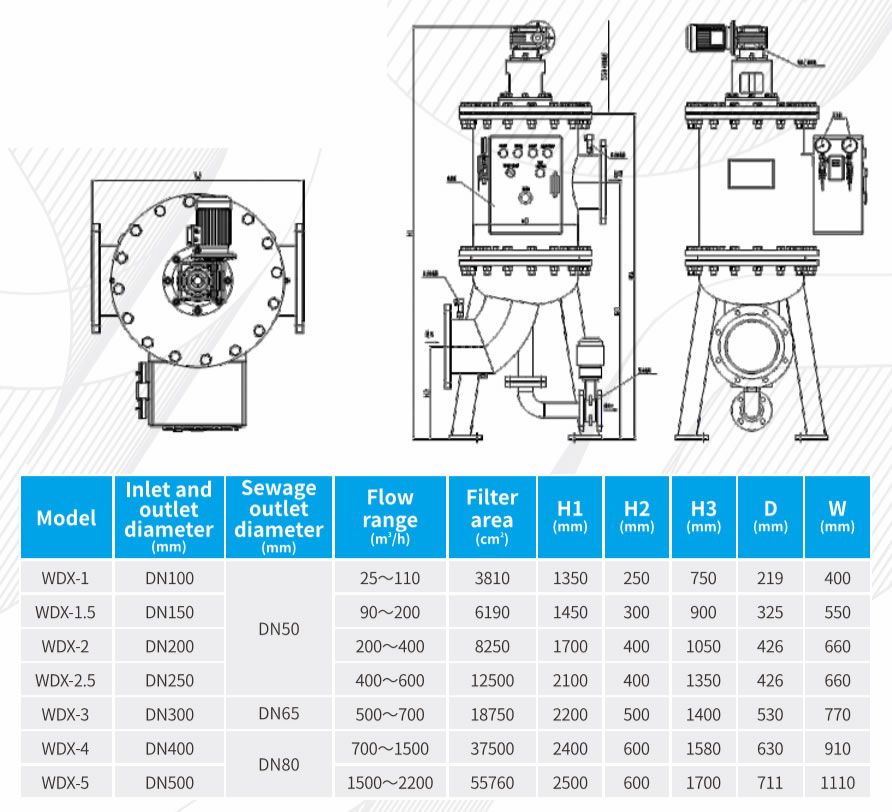

Filter Parameter

Mode Code